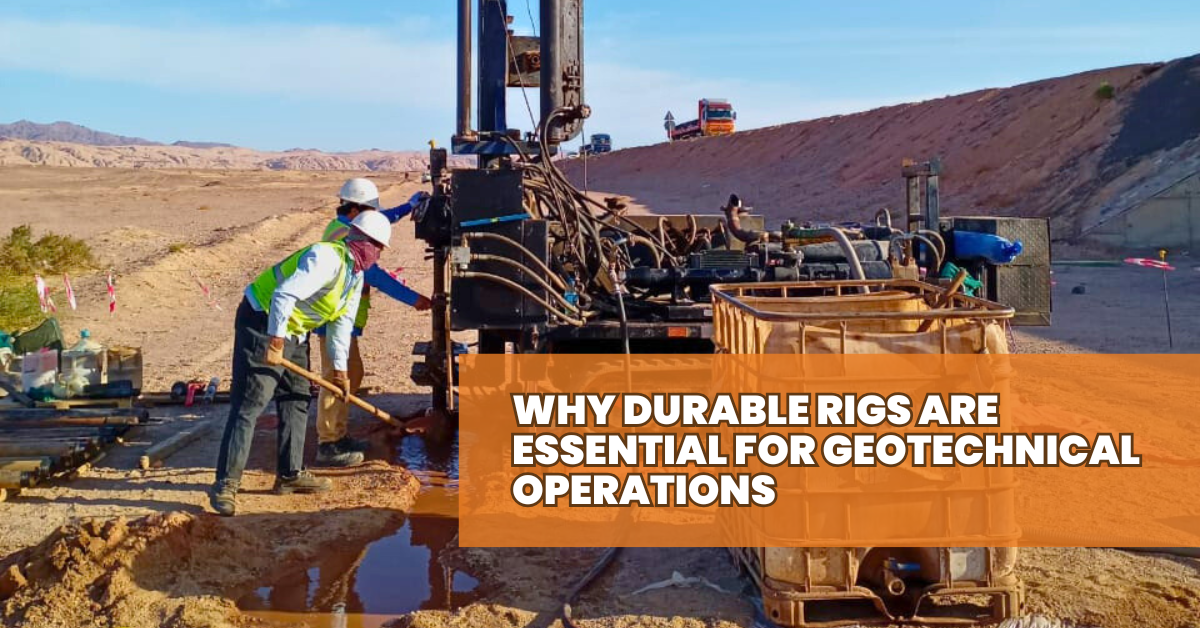

Geotechnical drilling is an application-intensive sector. Its nature means the soil and rock could range from very soft clay to extremely hard solid rock. Hence, it makes great sense to make durable rigs play a huge role in drilling for geotechnical operations for ensuring efficiency, safety, and value for the contractors. Making such long-term investment in durable rigs not only prevents more frequent downtimes but also maximizes success in conducting the soil investigations.

We are going to see in this blog why durability is essential in geotechnical drilling rigs, key features to look out for, and how reliable rigs for soil investigations can add operational efficiency to a project.

Importance of Durability in Durable Rigs for Geotechnical Drilling Operations

One of the most important factors when selecting a drilling rig is its durability. A long-lasting geotechnical drilling rig will have to be resistant to harsh conditions, extreme temperatures, and continuous use without frequent breakdowns.

For geotechnical contractors, this means:

- Fewer breakdowns than usual

- Lower maintenance costs

- Constant performance in demanding soil

- Increased equipment lifespan

Metadrill's long-lasting rigs for soil investigations are designed to last long and give the contractor a solid basis for drilling needs.

How Long-Lasting Geotechnical Drilling Rigs Make Operations More Efficient

The performance of geotechnical drilling equipment directly determines the efficiency of such operations. The longer the equipment lasts, the less downtime contractors will have in completing their projects on time and on budget.

- Higher drilling rate: Specially built to easily penetrate through harder soils

- Less frequent repairing: With less frequency of interruptions and costly delays

- Higher precision: Reliable soil investigation data

- Portable: Favorable to all terrains without it clogging and tearing

At Metadrill, we aim for long-lasting geotechnical drilling rigs that produce much more with excellent performance.

Challenges of Durable Rigs for Geotechnical Drilling Operations and the Need for Sturdy Equipment

Geotechnical drilling faces several challenges as follows:

- Challenging terrain conditions: Some soil types, such as rocky ground, demand powerful rigs.

- Heavy use: Full-time operation of drilling equipment puts a lot of stress on the elements.

- Severe weather: Heat, cold, and moisture accelerate wear on equipment.

- Rig mobility: Translocating from one site to another requires strong frames and high-quality hydraulic systems.

Why rig durability is important is obvious: if the equipment is not tough enough, then the contractors will be breaking down rather frequently and operational costs will get too high, too quickly. Metadrill rigs do not buckle under these conditions.

Keystone Features of Durable Geotechnical Drilling Rigs for Operation

A long-lasting geotechnical drilling rig must possess the following central features:

- Heavy-duty frame: Reinforced steel for added strength

- High-power drilling system: Efficient penetration in hard soils

- Hydraulic efficiency: Smooth running with minimum wear

- Advanced cooling systems: Avoid overheating in long hours of drilling

- Corrosion-resistant materials: Protection against environmental damage

Metadrill's reliable rigs for soil investigations are designed with these key features, ensuring durability and high performance in every drilling operation.

Tough Rigs Effects on Geotechnical Drilling Operations in the Context of Downtime

Equipment breakdown brings a lot of downtime and time delay to any project. More so, to a geotechnical drilling operations contractor, more downtimes signify the following consequences:

- Decreased downtimes: Rigs work for much longer with low repairs.

- Fewer breakdowns: Durable parts guarantee fewer mechanical breaks.

- Higher return on investment: Durable rigs are cost-effective in the long run.

By using Metadrill's durable geotechnical drilling rigs, organizations can increase efficiency and reduce surprises in their operations.

Maintenance Tips to Extend the Life of Your Durable Rigs for Geotechnical Drilling Operations

Proper maintenance is necessary to maximize the lifespan of your reliable rigs for soil investigations. Follow these best practices:

- Regular Inspections: Wear and tear on critical parts.

- Lubrication: Lubricate moving parts to prevent friction damage.

- Filter Replacement: Hydraulic and fuel filters should be changed according to the manufacturer's schedule.

- Bolt Tightening: All bolts and fasteners must be tightened to prevent structural damage.

- Monitor Cooling Systems: Overheating can cause major damage; always check coolant levels.

Metadrill offers specialized consultancy and support to assist contractors in ensuring that their drilling rigs for geotechnical operations remain in good condition for extended periods.

Safety is the Greatest Consideration in Drilling Geotechnical

Safe rigs for geotechnical drilling activities benefit from the following reasons:

- Reduced mechanical failure: Which serves to exclude sudden breakdowns that often result in accidents.

- Structural stability: Strong frames avoid tipping or collapsing.

- Enhanced control systems: Modern rigs feature improved safety capabilities.

- Reduced worker fatigue: Efficient rigs require less human intervention, therefore less stress on the operators.

Metadrill's soil investigation rigs are designed with safety at the forefront, ensuring secure and smooth operations on every project.

Conclusion

For a contractor who may desire reliability, efficiency, and long-term cost savings, investing in durable rigs is crucial. Where durability matters in drilling rigs is evident in how it reduces downtime, improves safety, and enhances overall drilling performance.

Metadrill makes geotechnical drilling rigs last very long in performance under the toughest conditions, providing unmatched reliability for soil investigations. Looking for reliable rigs for soil investigations? Explore Metadrill's high-performance rigs today and take your drilling operations to the next level!

Question to the public: